Home > Industry

Home > IndustryUpcut vs Downcut

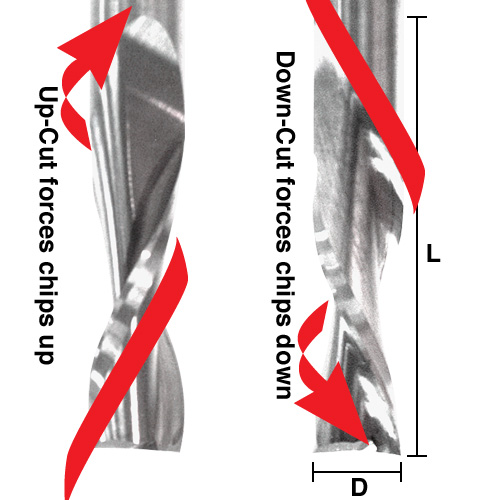

Up-Cut vs Down-Cut Geometry

Depending on which way the spiral goes on a cutter, you get a cutter that either moves the chips up or down. Whichever way the chips are going, there is also force exerted on the workpiece in the same directions. So, an upcut will move the chips up and out of the cut, and it will tend to pull up on the workpiece. BTW, the conventional endmill world refers to some cutters as left handed or right handed. This is not the same thing because it refers to the actual spindle rotation. You can get left hand (counter-clockwise) rotation router bits, but 95% of downcut bits are right hand rotation.

Why would you care about a down-cut bit?

An upcut is a conventional endmill for all intents and purposes. For wood and materials that may chip, it has the disadvantage that it wants to pull chips along the top edge. Since a downcut pushes down, it leaves a cleaner cut on top, but can fray the bottom edge.

Workholding is another issue. The upcut wants to pull up on the workpiece. If you’ve got a flexible workpiece (think plywood sheet vs a 1/2″ aluminum plate–the plywood is flexible), pulling up on it may bow it and make the cut inaccurate. A vacuum table helps a lot with this.

Okay, why not always use the Downcut, get cleaner cuts, and keep the workpiece firmly pressed down onto the table?

The answer is that the downcut forces the chips down to the bottom of the hole, which is far from ideal. It is less a problem with wood than metal, but it is still very much a problem. Consider using a downcut for a final finish pass where there are fewer chips to clear and where you want to avoid chipping the top edge of the cut.

Compression Cutters

Compression cutter

Imagine combining an upcut and a downcut and you’ve got a Compression Cutter. The flutes literally go one way for the bottom half of the flute length and the other way at the top. Compression cutters are for plywood, composites, and laminates. They’re used because the pull towards the middle of the cutter, which reduces chipping on both the top and bottom. Use one to cut completely through a sheet of plywood and you’ll have cleaner edges on both sides.

Don’t try to use a Compression Cutter on metal!

“Diamond Cut” Bits

Diamond Cut Router Bit

The Diamond Cut looks a lot like a wood rasp, and that’s pretty much what it is. They’re great for finishing cuts, but their material removing capacity is limited relative to other kinds of bits. Since they’re gentle on the material, they are often used with composites, PC board material, and other layered materials.

Chipbreaker

Chipbreaker

These are what the metal world calls a “rougher” or “corncob rougher”. The edges are serrated to break up the chips into smaller pieces and really move some material fast when roughing. They are very good for metal work.

View More(Total0)Comment Lists