Home > Industry

Home > Industry

Cutting tools come in a range of sizes, materials, and geometry types.

It is generally more efficient to use a combination of different toolpaths and tools to achieve a detailed model rather than assuming that a small tool with a smaller stepover is the only way. Often, a larger tool can achieve better finish results.

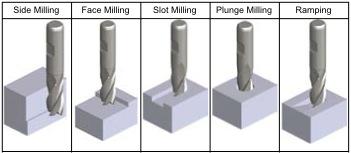

In end milling, the cutter generally rotates on an axis vertical to the workpiece. Cutting teeth are located on both the end face of the cutter and the periphery of the cutter body.

A ball nose end mill, also known as a spherical end mill or ball end mill, has a semisphere at the tool end. Ball nose end mills are used on workpieces with complex surfaces.

Choosing flat end mill vs. a ball end mill will determine the characteristics of the tooling marks (or lack thereof) on your model. Most jobs will benefit from strategic use of multiple size and shape tools for milling different features. End Mills are often used for roughing and 2D cutting and V-Bit and Ball Nose cutters are often used for finishing operations.

End geometry

There are up-cut, down-cut, compression cut end mills with varying numbers of flutes. End mills are intended to cut horizontally.

Up-cut, down-cut and compression cut determine the way the chips (cut material) are ejected and the smoothness of the surface. With an up-cut end mill, the chips will be ejected upward and the bottom of the material will be smooth. The down-cut end mill is the reverse by puching the chips downward and the top of the material is smooth. The compression end mill creates a smooth surface on top and bottom, which is perfect for pre-laminated woods.

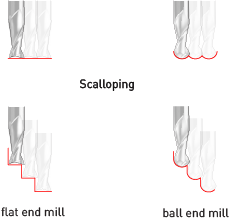

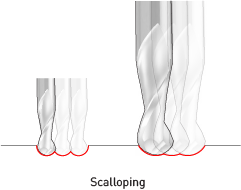

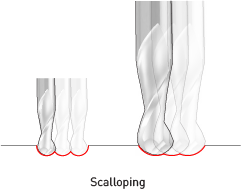

End mills come in a variety of shapes. The most common are flat end mills and ball end mills. Flat end mills will cut flat areas with no scallops. However, they leave a terrace-like scallop on non-flat surfaces. Ball end mills will leave smaller scallops for the same stepover value on sloped surfaces, but they will also leave scallops on flat areas.

Models can be tooled with a combination of flat and ball end mills. If only one tool will be used for all surfaces a ball end geometry will give a more consistent overall feel and smooth result.

Flat end mills can be Center Cutting and Non Center Cutting: Center cutting square endmills are essential for plunge milling. Non-center cutting mills are used only for side milling.

When choosing a ball end mill always chooses the largest size available. For the same stepover, a larger tool will leave smaller scallops, thus giving a smoother result. For a generally smooth model with some areas of fine detail, a large tool should be used for the overall job and a smaller tool should be used only to clean out detailed areas.

Larger tools cut more cleanly, have larger clearance, and stay sharp longer. The velocity of the cutting edge on a larger tool is higher for the same spindle speed.

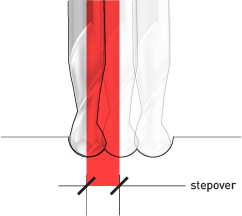

Stepover

Stepover is the distance the tool moves over between subsequent passes.

The stepover value (along with tool size) will determine whether the model has a smooth finish, or tooling marks are visible. It will also directly impact cutting time. Models with a smaller stepover take longer to cut.

Stepdown

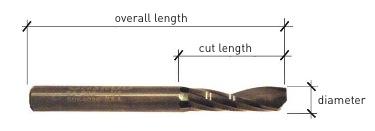

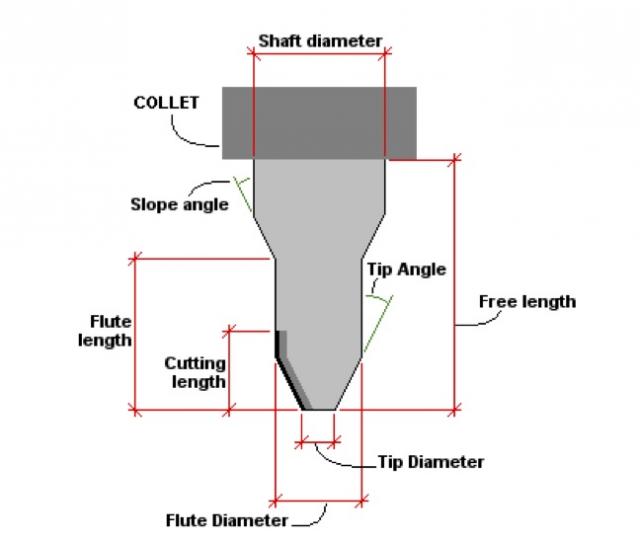

The length of the cutting area within the tool determines how deep the material can be cut in one operation –this is called the maximum stepdown. This stepdown value will only be used to its maximum when the material that is being cut is soft; for harder materials a smaller value is often required, setting the toolpaths to mill away layers of materials in separate passes.

Flute geometry

While the number, direction and type of flutes that a cutting tool has can vary widely, the tools most commonly used have two flutes and are up-cut spirals.

Some projects may benefit from other types of flute geometry. Contour cutting MDF or plywood sheets would benefit from down-cut spirals as the tool would push the material against the CNC machine table as it cuts rather than lift it.

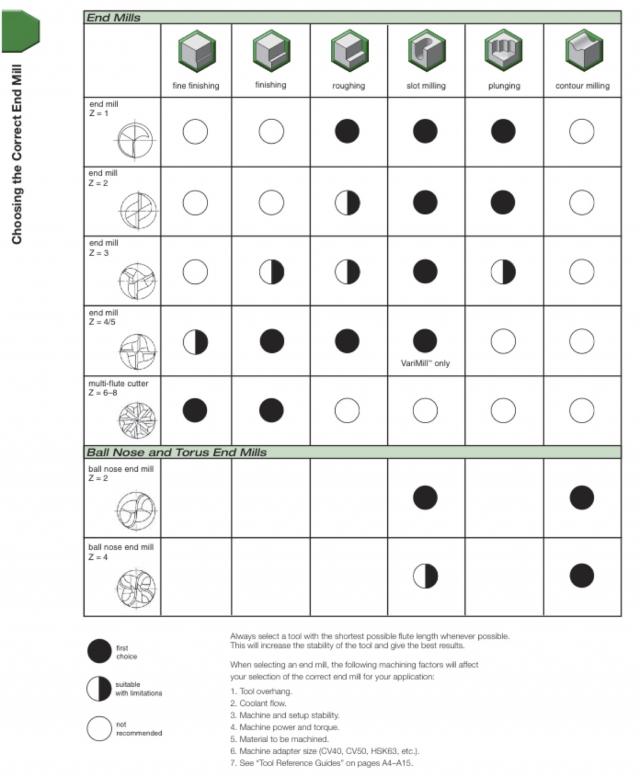

Number of Flutes

Single Flute - Allows for larger chiploads in softer materials

Double Flute - Allows for better part finish in harder materials

Multiple Flutes - Allows for an even better part finish in harder materials

As the number of cutting edges increases, your feed rate should increase to prevent burning and premature tool dulling. More flutes reduce chip load and improves surface finish if feed rate remains the same. The most common flute numbers for general milling operations are two (better space for chip ejection) and four (better surface finish).

Examples of applications using end mills:

Choosing end mills

Tool Materials

Material: end mills are made either out of cobalt steel alloys (known as high speed steel, or HSS), or from tungsten carbide in a cobalt lattice (colloquially shortened to "carbide"). The latter option is considerably harder, more rigid, and more resistant. Carbide tools can be run at speeds 2 to 2.5 times faster than HSS tools. When using carbide tools ensure that your machine tool is rigid with a solid spindle and that holders have little or no runout. Due to the brittle nature of carbide and the speeds at which carbide tools are typically run, rigidity is critical to prevent tool breakage.

Coatings: carbide cutters may be further coated with ceramics such as titanium aluminum nitride (TiAlN, aka AlTiN), titanium nitride (TiN), titanium carbon nitride (TiCN), and so on. Of these, the bluish-gray TiAlN coating is most common one, and by the virtue of reducing friction and improving hardness, it boosts the speed of metal cutting by up to 20%. It extends tool life.

View More(Total0)Comment Lists